Digitalization of Manufacturing Processes

The manufacturing sector worldwide is undergoing a profound transformation driven by digital technologies. This comprehensive shift, often referred to as Industry 4.0, integrates advanced computing, automation, and data analytics into nearly every stage of production. From initial product design and development to final delivery and customer service, digitalization offers manufacturers unprecedented opportunities to enhance operational efficiency, reduce costs, accelerate innovation, and foster greater agility. This fundamental reshaping of how goods are made and delivered across global markets is crucial for maintaining competitiveness and driving future growth in a rapidly evolving industrial landscape.

The Evolution of Modern Manufacturing Operations

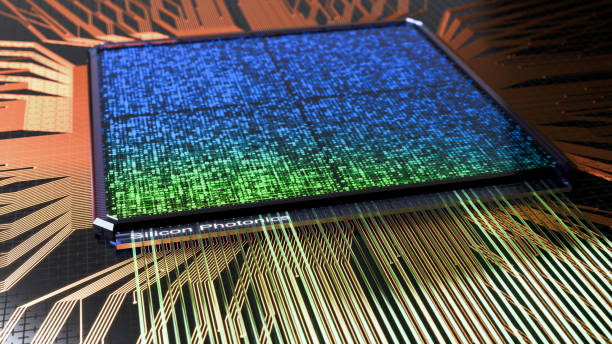

The history of manufacturing is marked by successive industrial revolutions, each introducing groundbreaking technologies that redefined production capabilities. Today, the digitalization of manufacturing operations represents the latest paradigm shift, moving beyond isolated systems to embrace interconnected, “smart” factories. This evolution is characterized by the integration of cyber-physical systems, the Internet of Things (IoT), and cloud computing, enabling real-time data exchange and analysis across the entire production floor. Such technological innovation allows for greater flexibility, speed, and personalization in manufacturing, empowering enterprises to respond with agility to dynamic market demands and consumer preferences, fundamentally transforming how products are conceived and created.

Enhancing Production Efficiency Through Automation and Robotics

Automation and robotics are central pillars of digital manufacturing, playing a pivotal role in optimizing production lines and significantly boosting operational efficiency. Advanced robotic systems are capable of performing repetitive, high-precision, or hazardous tasks with unparalleled accuracy and speed, thereby minimizing human error and enhancing workplace safety. Automated processes, powered by sophisticated software and artificial intelligence, streamline workflows, reduce downtime, and ensure consistent product quality across large-scale production runs. This seamless integration allows for continuous, high-volume operations, leading to substantial increases in output capacity and overall enterprise efficiency, providing a competitive edge in a global market.

Digital Transformation in Supply Chain and Global Logistics

The efficiency and resilience of the supply chain and logistics functions are paramount for any manufacturing enterprise, and their digitalization offers transformative benefits. Digital tools, including IoT sensors for real-time tracking, blockchain for secure transaction records, and advanced analytics for predictive modeling, provide unprecedented visibility into inventory levels, shipment status, and demand fluctuations. This data-driven approach facilitates optimized planning, significantly reduces lead times, and refines transportation routes for global distribution networks. Enhanced transparency and seamless coordination throughout the entire global supply chain lead to more robust operations, greater responsiveness to potential disruptions, and ultimately, a stronger competitive position for the enterprise.

Integrating Sustainability with Digital Technologies

Digitalization serves as a powerful catalyst for advancing sustainability initiatives within the manufacturing sector. By deploying smart sensors and analytical platforms, companies can meticulously monitor and optimize resource usage, from energy consumption to raw material input, thereby minimizing waste and reducing their environmental footprint. Predictive maintenance, enabled by data analytics, extends the lifespan of machinery and reduces the need for premature replacements. Furthermore, digital technologies facilitate the implementation of circular economy principles, promoting the recycling and reuse of materials. This integrated approach not only improves ecological impact but also enhances the long-term viability and public perception of manufacturing operations.

Adapting the Workforce for Digital Manufacturing

The profound shift towards digital manufacturing necessitates a significant evolution in workforce skills and roles. As automation increasingly handles routine and manual tasks, there is a growing demand for employees proficient in data analysis, cybersecurity, artificial intelligence management, and advanced robotics programming. Manufacturers are actively investing in comprehensive training and upskilling programs to equip their teams with the necessary competencies to operate, maintain, and innovate within these new technological landscapes. This strategic focus on workforce development ensures that human expertise remains a critical asset, fostering a collaborative environment where human ingenuity and technological capabilities converge for sustained enterprise innovation.

Leveraging Data for Enhanced Operational Efficiency

At the core of the digital manufacturing paradigm is the unparalleled ability to leverage vast amounts of real-time data for informed decision-making and continuous operational improvement. Sensors embedded throughout machinery and production lines collect granular operational data, which is then processed and analyzed using advanced algorithms and machine learning. This analysis identifies performance bottlenecks, predicts potential equipment failures through predictive maintenance, and optimizes various operational parameters. The actionable insights derived from this data not only fine-tune daily production processes but also inform strategic decisions regarding product development, market expansion, and resource allocation. This data-centric approach ensures ongoing refinement, driving maximum efficiency and maintaining a competitive edge for the entire enterprise.

The digitalization of manufacturing processes represents a profound and ongoing transformation that is redefining industrial capabilities across the globe. By strategically integrating advanced technologies such as automation, robotics, and sophisticated data analytics, manufacturers are achieving unprecedented levels of efficiency, fostering enhanced sustainability, and developing greater responsiveness to market dynamics. This continuous technological evolution empowers enterprises to effectively navigate the complexities of a globalized economy, champion continuous innovation, and construct more resilient, adaptable production systems ready for future challenges and opportunities.